Top 10 minor errors in IATF 16949!

- Utku Inan

- Mar 13, 2022

- 2 min read

After my article on the 10 most common nonconformities in 2021, which I published recently, this time I wrote 10 minor errors.

My source for this article is The International Automotive Oversight Bureau (IAOB) .

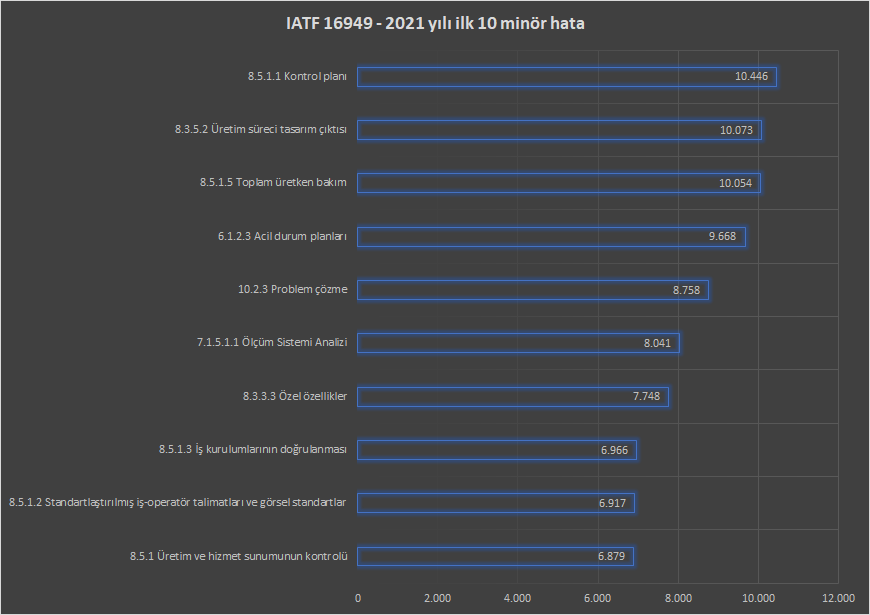

According to the IAOB database, a total of 253,857 minor non-compliances were found in the inspections carried out in 2021. The items in the top 10 account for 33.7% of these nonconformities.

Let's see which of these mistakes won the gold, silver and bronze medals?

8.5.1.1 " Control plan" in the eighth article of the gold medal standard

in the article. Auditors reported minor errors in the control plan source 10,446 times. This number is 4.11% of the total errors.

In the CQI-9 studies I conducted, I witnessed that control plans were prepared superficially. Therefore, I was not surprised that it took first place. I won't be arrogant about control plans here, but I would like to briefly remind you. A control plan should include five main elements.

Product features,

Process controls, (monitoring)

Tests, (in-process or final)

Measurement system analysis,

Response plans.

In the second place is 8.3.5.2 Production process design output . This error was encountered 10,073 times in 2021. They actually went head to head with the control plan. Having said that it is a very comprehensive subject, I am sharing below the first things that come to my mind regarding the subject.

Previously, many companies ignored all the design requirements of ISO and TS because they did not design the product, but IATF16949:2016 clarified that no IATF certified company can ignore the production process design. This process should be part of an organization's APQP process.

Organizations' production process design output process should include but is not limited to:

a) specifications and drawings;

b) specific features for the product and production process;

c) identification of process input variables that affect properties;

d) instrumentation and equipment for production and control, including capability studies of the equipment and process(es);

e) manufacturing process flow charts/layout including product, process and tooling connection;

f) capacity analysis;

g) production process FMEA;

h) maintenance plans and instructions;

i) control plan;

j) standard work and work instructions;

k) process approval acceptance criteria;

I) quality, reliability, sustainability and measurability data;

m) results of error-proof identification and verification;

n) rapid detection, feedback and correction methods of product/production process nonconformities.

At the last step of our chair is 8.5.1.5 Total productive maintenance . This item, which deserves the bronze medal as it was reported 10,054 times, constitutes 3.96% of the total errors.

I think the following should be taken into consideration in order to avoid any inconvenience from this article.

Total Productive Maintenance (TPM) should aim to:

Keeping equipment in good working order

Extending the operating life of equipment by slowing down degradation

Develop employee skills to competently operate and maintain equipment

Ensuring the safe operation and maintenance of equipment by employees

Ensuring equipment can operate in all quality critical areas

Reducing machine downtime due to equipment maintenance and repair

Guiding the organization to select/change equipment to meet its operational needs

Yes, after evaluating the first three a little, we can take a look at the top 10.

Comments